What We’ve Done

Our team members have worked on the following projects

-

Digit V4, V3, V2, V1 and Cassie

We worked on all 5 of Agility Robotics' robot versions, culminating in Digit V4: An autonomous humanoid robot made for work in industrial and logistics settings.

Mechanical Engineering - Sensor, Compute and Controller Integration, Custom Actuator Design, Thermal and Structural Design and Optimization, DFM for machined metals, injection molded plastics, thermoformed plastics, 3D printed plastics and metals, First-Article Assembly, Assembly and Manufacturing Documentation

Industrial Design - Concept development, Surfacing, CMF, Rendering and Product Photography

Management - Hardware Department and Mechanical Team Leadership

Systems Engineering - Requirements Development for Actuator Subsystems

-

Amazon Sparrow Robot End Effector

Multi-suction based robotic end effector for handling everyday objects of all shapes and sizes

Key Contributions - Generated architecture for compact and lightweight carbon fiber monocoque, mechanical deign of moving elements, positive and negative pressure pneumatic design and routing, design for very high cycle life, mechanical design of quick change tool coupling

-

Full Suspension Mountain Bikes

We developed an innovative method to machine full suspension mountain bike frames.

Mechanical Engineering - Design of all frame components, Suspension layout and analysis, Stress analysisIndustrial Design - Concept development, Surface design, CMF optimization for aesthetic toolmarks

Manufacturing - Development of new multi-axis machining method for mountain bike frames

See more at paladinbikes.com -

Keystone Tower Systems Spiral Welding Machine

A new more efficient and cost effective way of manufacturing wind turbine towers via tapered spiral welding

Key Contributions - Mechanical and structural design of runnout module (the section of the machine which receives the completed tower as it is welded). This includes structural weldments, rolling and articulating elements for carrying and adjusting to the load and shape of the tower, force and contact stress analysis and machine electrical and controls integration.

-

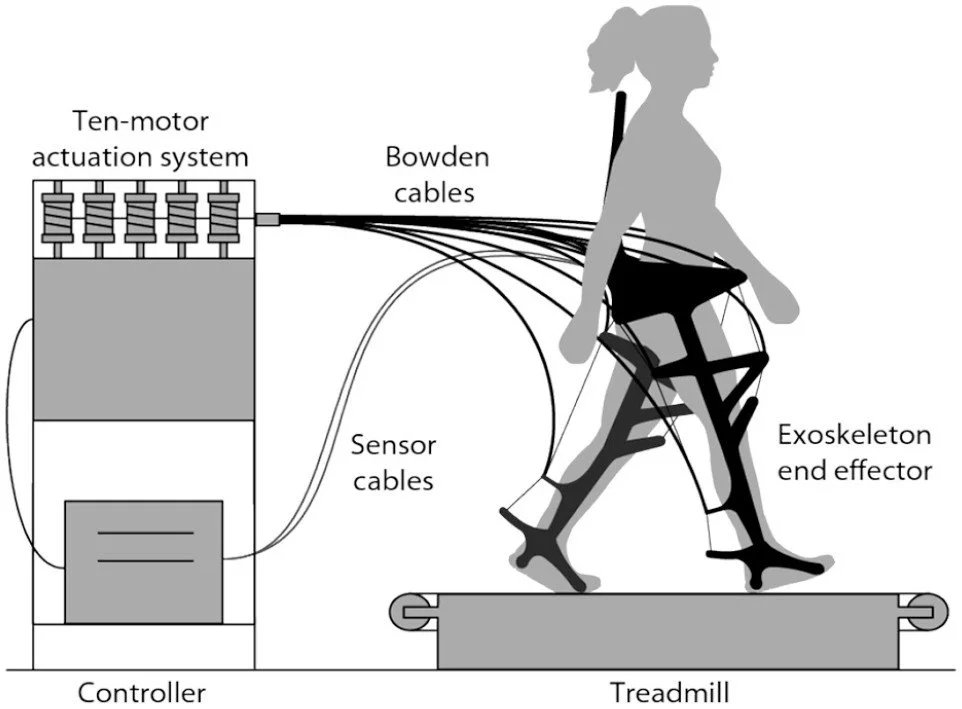

Stanford Biomechatronics Lab - Exoskeleton Emulators

Development of exoskeleton emulators used to discover optimal locomotion assistance strategies and simulate new exoskeleton hardware.

Key Contributions - Mechanism Design, Structural Design and Optimization, Human Body Interface Design, Controls Development, Scientific Writing and Illustration, Hardware Testing, Human Subject Testing, Design, Build and Setup of Hip-Only Variant for Georgia Tech

-

Dexcom G7

Wearable Continuous Glucose Monitor

Key Contributions - Mechanical Design and test of a high speed reliable mechanism for nesting the blood glucose sensor within the needle for deployment under the skin during application, mathematical modeling of sensor shape

-

SQZ Biotech Cell Processing Equipment

Lab-based processing equipment used to perform SQZ membrane disruptive cell therapy process (illustrated above)

Key Contributions - Mechanical design, electrical design, electromechanical integration, industrial design, software programming, user interface, pneumatics , fluid flow and liquid control mechanisms, thermal process control, heating systems, thermoelectric cooling systems, full circulation liquid cooling, agitation mechanisms, sterile and wash down equipment design

-

Custom Bike Components

We work with bicycle companies to bring their products to life. From prototyping to full production runs.

Key Contributions - Industrial design, mechanical design, structural analysis, kinematic analysis and in-house machining